I start and finish projects; that's what I do best.

I've been involved in a very diverse range of experiences. Not just as a casual observer, but as an active contributor. Everything in this world relates to everything else, and a breadth of experience is highly valuable. I have composed this portfolio together to illustrate the depth to which I have been involved in all these areas. I never want to misrepresent my experience, but I want to avoid the mistake of downplaying the reality of what I have accomplished.

This portfolio represents my past. The future I am working toward is outlined in my Space Management Roadmap. My hopes are to be among the prime players in the growing Commercial Manned Space Exploration Industry.

| US Patent: Rock Climbing Port-a-ledge |

|

| We

can start off with the patent I filed in October '04 for a

port-a-ledge

for sleeping on rock climbing routes requiring multiple days to climb.

It’s a good eye catcher, and it illustrates experience in mathematical

analysis, manufacturing, ingenuity, intellectual property, and the

ability to start a project and see it through to completion. The attached article (Ledge Development.doc) was submitted and selected as one of the winners of the Collegiate Entrepreneurs Organization and NCIIA Technology Competition (Technology Awards; p. 4). It illustrates the development process and business prospects for the ledge. It is significant that I designed and built this ledge on my own, everything from machining all the joints to sewing the bed and suspension cords. The attached structural analysis is pretty straightforward (Structural Analysis.doc). This analysis is for the dual climber model of the ledge, not the single model shown here (right). I don’t recall what grade I earned in my structures class, but I do recall how to apply what I learned. It was clear that I didn’t want to build a business around this single product, so it would be best to patent it, and license it to an established company. I did some personal research on patent law, then happened to find a class I could take on intellectual property. After the class, I decided to draft the application on my own, for the learning experience, and then hire a professional to complete the process, to ensure it was done right. Simply put, I have a functional understanding of the legal and business implications of intellectual property, and how aspects of intellectual property effect industry. You can find more on the ledge if you visit the web site I built to use for marketing it to the established climbing companies. www.speedledge.com. (You must use MS Internet Explorer for the speedledge site to work properly) |

Zion Canyon; Utah - Moonlight 5.10/C2 |

| Return to Top |

| Satellite Test Chamber Control System Northrop Grumman |

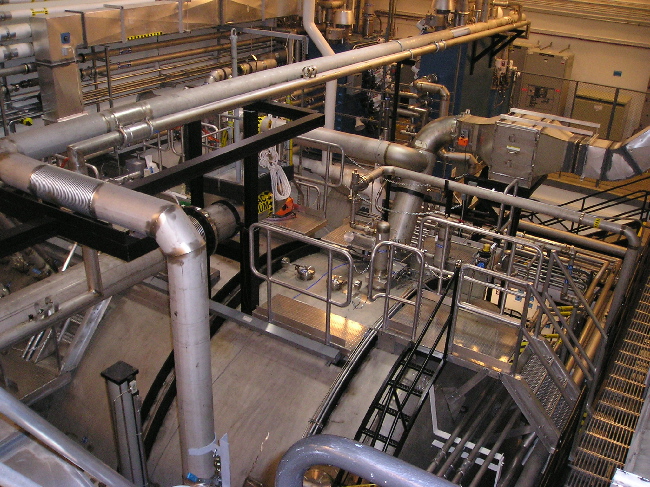

We control everything back here... |

... to simulate space in here. |

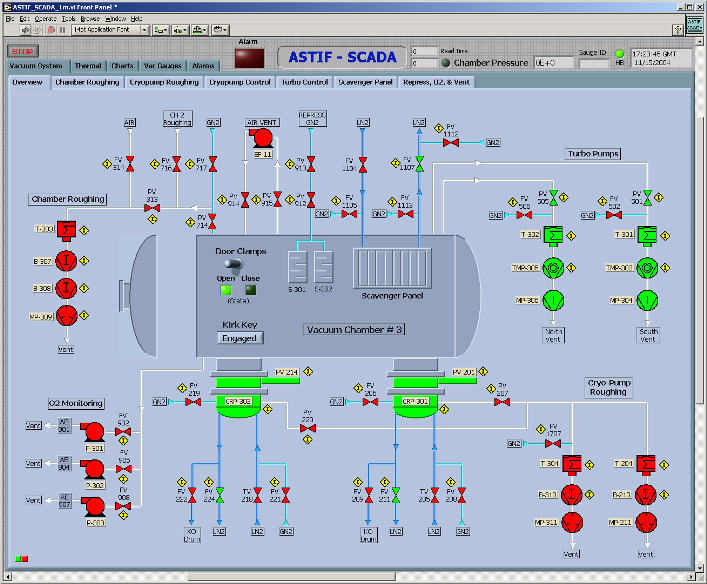

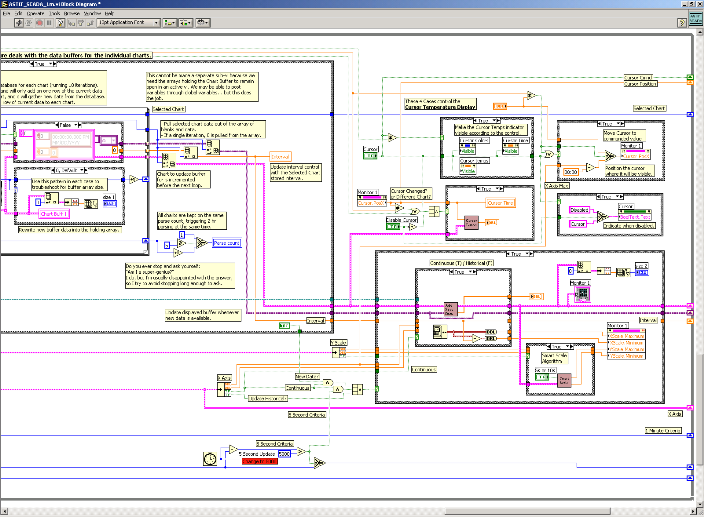

| Satellite Test Chamber Control System This project required programming all the software to monitor, command, and log data for the entire vacuum chamber test system, as well as integrating new equipment. This chamber is 26 ’Diameter, by 40’ deep, with over a thousand sensors, valves, pumps, and components. The programming involves 12 different sets of software, all running on 6 independent (but interacting) process controllers, requiring nearly 4000 tags in the whole system, with 5 local and remote user interfaces. The initial challenge was learning the system, with all the components and their interaction. Once I understood the existing setup, then I could move into designing / redesigning for our needs. The original control system for this thermal-vac test chamber was hastily implemented, and consequently had several recurring bugs. I expressed my interest in the project with the intent to improve the reliability, streamline the processes, implement a reliable and accessible database, and add several user friendly bells and whistles. When I started this project, I set forth an expected schedule of 14 months to completion, with mile markers every 3 months or so. My manager thought the schedule looked good, but when our lead facility engineer saw it, he laughed: “Ok. Multiply that by 3 and that might be your schedule.... You work quickly though. You might get it in 2 years.” I met each of my mile markers along the way, and completed the project exactly 1 month early, March 31, 2005!!! The end result is a control system superior to what we initially envisioned, no bugs or glitches (after two week long tests), and a database that users can easily and intuitively access. The early finish wasn't an accidental slip of circumstance. Our facility schedule changed and I had to accommodate. We wanted to run a baseline test at the end of March, and that included our Control System. We saw this coming in December, so I spent the next three months working overtime, and the last two weeks on an 80 hr schedule. If I finished in time for this baseline, we could have the project completed. If I missed the deadline, it would drag out for another couple months. My manager was understanding if I couldn't make it, but I wanted it finished, so I put in the work and got it done. Technical aspect: I used LabView for the primary user interface, and LabView DSC for the database and tag engine. The process controllers are Allen Bradley SLC/505 series, programmed in RSLogix 500 (ladder logic). Local user interfaces for the process controllers are Allen Bradley PanelView touch screens. Other equipment interfaces through LabView on GPIB and RS 232. System Control Interface (LabView) - Built from scratch System Database with User Access Interface (LabView DSC) - Built from scratch Thermal System ladder logic (RSLogix) - Major changes Thermal System local interface (PanelView) - Built from scratch Vacuum System ladder logic (RSLogix) - Minor changes Vacuum System local interface (PanelView) - Minor changes Vacuum Gauge communication (LabView - GPIB) - Built with LabView Electronic Equipment Chillers (LabView - RS232) - Modification and Integration Nitrogen Thermal Control Units (RSLogix and PanelView) - Led a summer intern to make changes Data Analysis tools (VBA in Excel) - Led a summer intern to program from scratch |

LabView -

Vacuum System Overview screen.

|

LabView

back panel (code) segment for the charting routine.

|

| Return to Top |

| Hired Minds: A Guide for Graduating Engineers |

|

| I have written Hired Minds to serve

as a transition guide for graduating engineers, and am currently

working on publication. The idea for this book came from the

Engineering Resume Workshops

noted below. The book uses the personal

experiences of over two dozen beginning engineers to illustrate the

several paths for developing engineering experience as an undergrad,

landing the job you want, and starting off right as an engineer. It

covers the office, team, and personal work dynamics that are essential

to successful engineering, especially during the first year. The book

is designed to accompany University senior design project courses,

helping to successfully bridge the transition from education to

industry. I first completed writing Hired Minds on July 11, 2005, at 3 pm. Following that, I had the manuscript reviewed by several relatively new engineers. The next round of reviews came from several senior managers, including my Site Director at Northrop Grumman, our head of Employment and Recruiting for nearly thirty sites, and a Program Manager at Boeing. When published, the work will be just under 200 pages. I had never written a book before, but the process and organization came rather intuitively. However, I must say that in order to write something like this, you have to be in the right frame of mind, and you need dedicated segments of time to lock out the world and focus. Overall, it has been a very valuable experience. |

*I'll post the cover here when it's ready. |

| Return to Top |

| Visual Basic Data Analysis Northrop Grumman |

|

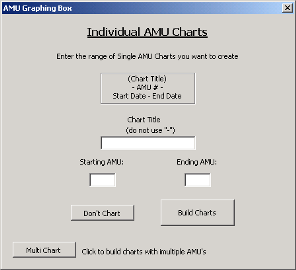

| When I started with Northrop

Grumman, I was hopeful to build my

experience in the direction of automation, particularly regarding the

mechanical / software interface between hardware and programming. I had

enjoyed my previous experience in this area, and it was an interesting

area to enter. The first assignment I was given at NG was to chart eight months worth of temperature data from previous thermal-vac tests. While showing me the data format and what knowledge they wanted to gain from the data, my manager commented “It would be nice to have a macro where we could just push a button, and have all this done for us.” I replied “I might be able to do that.” I had never so much as opened the Visual Basic Editor in Excel, but I had heard from a few people in the past that Excel could be programmed to manipulate data like this. I spent the next week and a half with the help menu, books borrowed from co-workers, and Google, developing a macro that processed and charted all the temperature data just like we wanted it. The data that they expected would take me a week could now be processed in three minutes. About two months later, we had a bank of heaters in the vacuum chamber fail during test. During the next 48 hours, the engineers who knew the chamber and it systems were over there trying to determine if the payload was safe, what happened, etc. When it was all done, Brent (my mentor) found me to say “That macro you wrote saved us hours, and hours, of crunching data to find out what happened. Could you make another macro that would…” And so began the automation of the routine data analysis for two test chambers, and our radiometric calibration data. 9 Tools total, including one for our Payload Thermal Analysis team. With all of the macros I have written, I have done everything I can to make them robust, and very user friendly. I have programmed each macro for other non-Excel people to use it. I put together a workshop for young engineers, and posted samples that you can download from my web site (VBA for Engineering Applications). |

Dialog Box from the RGA Macro. |

| Return to Top |

| Engineering Student Workshops |

|

| While

at NG, I have had the opportunity to participate in recruiting

new engineers from universities, interviewing candidates of various

experience levels, and working with the summer intern program. On my

first recruiting trip with NG I interviewed over 30 engineers, and

noticed that many students had more valuable experience than what they

represented on their resume. A couple months later, while talking with

a friend who was graduating soon, I caught the idea of running an Engineering

Resume Workshop for the students prior to the next career

fair. In two weeks I contacted the appropriate professors at BYU, put

together the presentation, and flew out to run the workshop. It turned

out to be a tremendous success with over 60 engineers showing up, and I

was working with individual engineers on their resumes from 6 pm until

midnight. I also helped several through email who couldn’t stay that

late. Toward the end of that semester, I was making a trip to Utah to climb a multi-day wall with my brother, and decided I would take the opportunity to also teach a mini-course on VBA in Excel for Engineering Applications. The course notes are available on my web site, along with several demonstration macros. Over the next few months, I received emails from a few engineers who applied what they had learned through the workshop. I have run resume workshops at BYU each semester, as well as a workshop through AIAA for students in various universities in the Los Angeles area. Each of these experiences have been highly valuable for the participating students, as well as myself, in gaining exposure to so much diversity in engineering talent, experience, and background. It is significant to note that these workshops were not previously offered. I saw the need to be filled, organized the workshops on my own, and contacted the faculty to get approval to hold these workshops. |

Zion Canyon; UT - Space Shot C2 No relevance to the workshops, except that it's from the climbing trip mentioned. |

| Return to Top |

| Aerospace - Government Washington DC Visit - AIAA Through regular attendance of AIAA meetings and events, I meet many people diversely involved with various aspects of the Aerospace Industry. I was invited to join a group from AIAA to meet with several Senators and Representatives in Washington DC. This trip was far more valuable than I had anticipated. We made our each visit in small teams with different people each time. The various reasons each individual had for supporting the same AIAA agenda was very enlightening. The government side of the discussion was the most eye opening. The Senators and Representatives (and their staff) have so many issues that they are responsible for dealing with that they need individuals concerned about their industry to schedule times to discuss their industry and opinions about what should be done. If individuals do not take the time to communicate with our elected representatives, they will have a relatively limited basis of information and rationale to formulate their decisions. One of the most valuable discussions I took part in was at a cocktail party at the end of the day. Our elected representatives have taken the responsibility to make decisions for legislating and funding programs, but the citizens have an equal responsibility to work with these public officials. In a nutshell, there is a whole dimension of Aerospace I had previously been only vaguely aware of. I include this experience in this portfolio because I am aware of how valuable it is to a rounded understanding of the industry. Engineering is the core of aerospace, but as providers of technology for our national defense, there are several other aspects that are indispensable to success. |

| Return to Top |

SpaceHub.org - www.spacehub.org When I decided that commercial space exploration was the direction I wanted to take my career, I immediately began investigating the industry. The societies and membership groups are always advertising themselves, but I was interested in the businesses and technologies that would make commercial space a reality. I wanted to know where it would be most effective for me to personally focus my talents within the greater effort being made. I began collecting my own research on the industry, and then spoke with a friend at work about posting the research as a web site where we could generate collaborative input from the worldwide space community. A short time later, I spent two solid days with a friend in the web programming world building the framework for the site, and it has grown from there. Having the research as a web site has proven valuable for myself, as well as the increasing visitors to the site. We have a long-term vision regarding what we would like to use SpaceHub.org for. Ultimately, we would like to use the site as a design forum for the engineering necessary for a sustained human presence in space. Modeled after the astounding success of the Open Source community in programming, we would like to draw from the worldwide talent pool in engineering. There are many significant challenges to this, but we believe the idea may have merit when we have the right tools. There are many differences between programming software and designing spacecraft, but who would have thought Open Source could achieve what they have already? It's a possibility. Capitalism and individual ambition are an astounding combination. |

| Return to Top |

| X Prize Volunteer Crew Manager August - October 2004  Mike Melville on SpaceShip One after the first civilian flight into space; June 21, 2004. The X Prize was a $10 Million competition

for the first privately funded team to successfully launch a vehicle

with the equivalent of three human passengers into sub-orbital space,

and repeat the trip within two weeks. When I heard there was going to

be a test launch for Burt Rutan's SpaceShip One, I gathered some

friends and went out to Mojave for the event. While there, I met the

team responsible

for running the X Prize, discovered they needed help with the upcoming

launches for the

$10 million prize, and was more than happy to join up with them.

I immediately started meeting with the X Prize team to prepare for the competition launches that would be held in the next few months. Because of my familiarity with the airport, comfort with working with groups of people, and reliability with a few initial projects, they asked me to co-train and co-manage the entire volunteer team for the competition launches (over 150 volunteers). I prepared the training presentations, and worked with the sub-team leaders to organize our efforts. During the event I co-managed the volunteer crews, ensuring they had the resources and support they needed. Everything went through smoothly, the launches were an event for the history books, and we were happy to be a part of it all. *On a personal note, the first launch on June 21st, 2004, was a very influential event in my life. Several years earlier, I had dismissed the notion of space travel because I wasn't interested in sparring against other people to hitch a ride on the Space Shuttle. Furthermore, I strongly believe that indiviuals should earn their means to go play / explore in space. Seeing SpaceShip One successfully developed under private funding, at 2% to 5% of the cost of a single shuttle launch, validating a legitimate business market, I realized that a frontier I thought to be closed was actually within reach. I want to walk on the Moon, after 100 people have been there before me. I want to earn my way there, and ensure the industry infrastructure is present to accomplish this. This is the motivation behind my Space Management Roadmap. |

| Return to Top |

| El Capitan; Yosemite - Tallest Cliff in

North America August 2004

|

|||||

| Return to Top |

| Project Manager - Dual Shuttle Vacuum

Forming Machine (Sorry, no

pictures right now)

This eight month project was more like a pre-graduation full time contract than an internship. Quality Plastics wanted to increase their vacuum forming capacity, and wanted to implement some features into their machine that they could not buy from the regular suppliers (such as distortion graphics and pressure forming). The machine had been modeled in CAD (IDEAS) when I arrived. I was responsible to bring the machine from computer screen to reality in 8 months. This machine is a plastics vacuum forming machine with two forming stations on opposite sides of a shared infrared heating station. It has a forming capacity of 4’ x 5’ sheets, and the entire machine is 18’ long, 10’ wide, and 9’ tall. The work pieces are clamped pneumatically, carried by stepper motors, and the forming platens are hydraulically actuated. Because the company also wanted to use this machine for pressure forming and distortion graphics, it was essential that the machine be very rigid with high positional repeatability. The first thing I did upon arrival was to study and become familiar with the machine, its intended uses, and what had driven the design decisions. Next I laid out a schedule covering all the tasks that needed to be performed to complete the machine, starting generally and branching down to the detailed components (based on a GANT Chart format). Before beginning to order materials, I composed a budget including all the known and estimated expenses. Finally I began ordering materials and executing the fabrication and construction. Through all the machining, welding, etc, it was very interesting to see first hand how different materials react to different manufacturing processes. Gaining exposure to the various materials, coatings, and processes that enhance material properties opened my eyes to a whole range of possibilities to manipulate component performance. To make some specific components, I took advantage of the expansion ratio between steel and aluminum in building the tooling. I used metals of different hardness, damping, and bearing properties for function specific components (bronze, brass, “gray iron,” UHMW polyethylene, etc.). I thoroughly enjoyed managing this project and driving the progress every day on it. As the project started gaining momentum, I was given more people to work for me. For two months at the peak of the project, I had 5 others working under my direction, some skilled and some requiring training. All the fabrication decisions and many detailed design decisions still had to be generated as we went. Designing all this fast enough to keep my workers busy led to six weeks in a row of working between 65 and 75 hour weeks. Making that machine grow so quickly during that time was certainly worth the focus and dedication, and I still made time to go mountain biking 2 – 3 times a week. |

|||

| Return to Top |

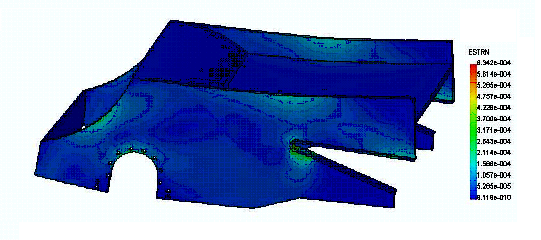

Asphalt Zipper - Senior Design Project; BYU

No fancy write-up yet, just pictures. But... our team of five designed EVERYTHING for this machine, the company's shop built it, we tested it, and it met or exceeded our performance specifications. It was a good Capstone project for our degree. .  |

|||

| Return to Top |

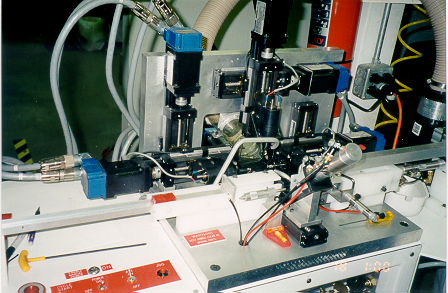

| Automated Dice Drill I programmed two of these. The first was a 14 Axis machine with two drilling stations, and the second used only one drilling station with a proprietary feedback mechanism. I programmed the second as a side project while I was working on the Dual Shuttle Vacuum Forming Machine. Both machines drilled repeatably within position and depth tolerances of +/- 0.002”. We used servo motors controlling the axis, and brushless servo motors for the drills because of their high torque and small size.

The real challenge was in optimizing the process, and at the same time making it idiot proof. The program was run through a PC interface (Think-n-Do Software) communicating with the servo drivers and I/O units controlling the pneumatics. There were many commands that had initially been programmed to unnecessarily wait for previous operations to finish. There were many more commands that could be triggered inadvertently, resulting in crashing the machine. The challenge was in finding which operations it was necessary to wait for, how long to wait for them, how to flag commands prior to their natural sequence, and to insert the necessary interlocks that would prevent these processes from beginning impulsively while allowing them to begin when desired. In total, I brought the cycle time from 12 seconds down to 5 seconds, and worked out (apparently) every program bug. It is significant to note that when I was hired as an intern, it was never the company's intention to give me responsibility over this machine. Among my other responsibilities, I was helping their full time engineer develop the program and build the smaller mechanisms to finish the mechanical functions of the machine. More often than not, I was the one left to dig through and analyze the maze code, to understand the problems we were running into. Over time, I became the expert on the machine, and they gave me full responsibility for it. When we finally delivered the machine (on time) to the company we had contracted to build it for, everything went perfectly. The President of Quality Plastics planned on me delivering the machine and spending the day before he came setting it up. He arrived expecting to stay for three days trouble shooting the inevitable problems that would appear. When he arrived, he saw I had everything under control and gladly flew out the next morning, confident that I could handle anything that came up, and leaving me to train the new owners and operators. |

|||

| Return to Top |

| Composite Human Powered Vehicle |

|

| Composites

have always been fascinating. The best part of this

experience is that everybody who was on the team was there simply

because they wanted to have a good time, and we'd learned enough

engineering to do it. We gained exposure to composites in both pre-preg

and wet lay-up, auto-clave curing, and the functional performance of

the materials (we broke a couple parts) The body and frame had been

designed by a pervious year senior design team, so we didn't get much

on that aspect. We saw how composite materials can be fabricated to

produce very specific and directional performance. They’re not a

cure-all design material, but can be very useful in the proper

applications. My friend and I started this team. He had the idea and we both picked it up and ran. He took care of all the logistics and paperwork for the team, and I got to take the role of the Chief Engineer (partly due to circumstance, and my previous experience in a machine shop and with composites). The rest of the team was a mix of friends and random recruits conveniently interested in exactly what we needed people to take responsibility for. |

HPV Team and vehicle after winning first in the Utility Race at the ASME national competition in Reno, NV. |

| Return to Top |

| Investment Banking |

|

| In

January ’02, nearly a year before graduating in Engineering, I

discovered investment banking, and spent that entire year doing

everything in my power to take my career toward Corporate Finance, or

Mergers and Acquisitions. In addition to my engineering courses, I took classes in Accounting and Corporate Finance. One of my projects was an investment analysis of Sylvan Learning including all the historical financials and projections, and other dirty work to become familiar with the industry. To become more familiar with the industry, I wrote a term paper on The Rise and Fall of Enron for my Technical Writing class (document re-formatted). After grading it, my professor suggested that I consider writing for the Wall Street Journal as a career. Not my type of job, but I was flattered. I spent about an hour every day reading the WSJ, focusing in the finance section. I also read several books, including the history of Goldman Sachs, Liars Poker, and Charles Schwab. I began networking with investment bankers in New York, as well as San Francisco, Los Angeles, Salt Lake, and Denver. I spoke with people in all aspects of the industry from traders, to analysts, to I Bankers, covering both bulge bracket and mid-market firms. In August I took a trip to New York to meet many of the people I had spoken with on the phone, and to interview with a couple of the bulge bracket firms. That fall I was told by two separate individuals, one interviewing and the other networking, “You know more about this industry than 90% of the people I’ve spoken with.” I tried to make it to Wall Street, but in the end I failed. The Dot Bomb of ’01 had something to do with that. I'm glad I failed, but I'm glad I tried. My experience in that industry has been very valuable in understanding the Aerospace Industry, both with the large and smaller corporations. On a side note... It's funny, the average GPA for undergrads finishing the Business School was 3.6, the highest at BYU. The average for undergrads finishing Engineering was 3.4 (my GPA), the lowest at BYU. The Business classes I took were easier than any engineering class I ever took... and they were famed to be the toughest in the business school!!! Business students feared these easy classes!!! Where's the Justice? |

. |

| Return to Top |

| Manufacturing Emphasis I did an emphasis in Manufacturing along with my degree in Mechanical Engineering. I started at BYU in Manufacturing Engineering, but switched to Mechanical because it opened more opportunity for the future. Early on, an Uncle and cousin who were engineers inspired me to develop an appreciation for the manufacturing side of engineering. It's easy to overlook how much brain work is required to design the right tools for creating precision and high tech products. As part of this emphasis, I took graduate courses in Manufacturing Machine Design, and Operations for Manufacturing Management. The later course was my favorite, focusing on the dynamics of variation, Just in Time, throughput, work in progress, cycle time, etc, in all aspects of the operation. We built mathematical models of several manufacturing systems, including this final project where we optimized the design for a manufacturing operation. As a whole system it looks pretty complex, but like all complex systems, it becomes simple when taken one part at a time. |

| Return to Top |